Posts Tagged ‘holden commodore’

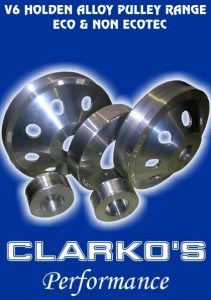

Holden v6 Commodore Aluminium pulleys

Holden Commodore Aluminium Pulleys – Why are they so wonderful to use?

If you have a Holden V6 engine and you would want to give it an extra bit of edge, maybe you could try going for an Aluminium billet pulley. Holden commodores with Holden V6 engine in the ecotec (series 2) and non ecotec (series 1) comes custom fitted from the factory with a press steel pulley. This press steel pulley drives the alternator, power steering, water pump and other accessories. Aluminium billet pulleys are lightweight and nicer for your engine. These replacement OEM pulleys are made of the highest quality billet T6061 billet aluminium, which is much better than the cheaper cast aluminium or the steel ones available.

Using OEM replacement pulleys dress up your engine and are wonderful to have for show cars. These replacement OEM pulleys are useful for ecotec engine power steering, alternator, and water pump whereas reduction drive pulleys suit non ecotec and ecotec series 1 and 2 engine. They are 20% larger than the standard one available in power steering, alternator and water pump.

Replacement OEM pulleys are a replacement bolt on bolt for ecotec V6 engine (series 2). These are available in the same size as the factory-fitted holden pulleys. Hence, these can easily replace the factory ones, and you can do the replacement yourself using the same sized fan belt.

The process by which the replacement OEM aluminium pulley can be fitted is very easy is explained here: First, you need to remove the fan belt. This can be done by undoing the bolts that hold the power steering, alternator and water pump pulley. Now, remove the old press steel pulleys. Attach the new billet OEM aluminium pulleys in the empty place. Now, tighten the bolts back on. Attach the fan belt, and your engine is all spruced up.

Why must you use an OEM aluminium reduction pulley?

The main use of reduction pulleys is to slow down the RPMs (Revolutions per minute) of parts such as power steering to avoid cavitation, oil boiling and frothing, and the breaking down of the consistency of oil. These are 20% larger in size thus it is easier for them to do so especially for race cars. These are used for water pump to avoid cavitation and decrease the speed of the water that goes through the engine block and that can reduce the cooling efficiency of an engine. They are also used for alternators to avoid over revving of the alternator that can cause it to fail and stop working.

These pulleys have been used extensively in race cars such as modified production, wingless sprint cars and many other speedway classes and other race divisions available in ecotec engine series 1 and non ecotec engine series 2.

These pulleys are especially popular and widely used in Holden V6 engines across Australia and New Zealand. They have been race tested and have a proven performance record. These are a great accessory to have for your engine

CLICK HERE TO VIEW OR FIND OUT MORE

HERE IS A YOU TUBE VIDEO TO SEE MORE